#etrierfrein #moto safety #mechanics

Ever since Neanderthal invented the motorcycle, hominids have been constantly improving their braking systems. A quest that continues to this day. And while the brake caliper may seem primitive in design, it actually conceals many subtleties. Radial or axial articulation? Floating or fixed? Asymmetrical pistons or not? In this article, we share with you all the information you need to understand how a brake caliper works and how to choose the right one.

How does a motorcycle brake caliper work?

Let's start this article with the basics: how does it work? The general idea is simple: press the pads onto the disc to slow down the rotation of the wheel. And since nothing is lost and nothing is created, this energy is transformed into heat (and your pads lose material).

But what actually happens when you jump on the brake lever? You activate a pump - the famous master cylinder - which sends the precious brake fluid from the reservoir to the calipers. The pressurized DOT 4 or 5.1 pushes pistons that slide in their cylinders to compress the pads on the disc. In fact, your braking system works exactly like a car's hydraulic jack.

![]()

What is a brake caliper made of?

- The caliper body: this can be one or two-piece (more on this later).

- Pistons: their number varies, but their mission remains the same: to push on the brake pads.

- Cylinders: these are the housings in which the pistons slide.

- Piston seals: these provide a seal between the piston and its housing. In simple terms, they prevent brake fluid from running straight across your disc.

- Dust seals: protect pistons from life's hazards, such as mud, sand and pad residues.

- Pads: do we really need to go into detail about them?

- Bleeder screw: aptly named, it removes air from the fluid circuit.

What are the differences between a floating and a fixed brake caliper?

What's the existential problem facing the caliper since the dawn of time? For optimum braking, the disc must be perfectly centered between the two pads. In fact, the pads must press against each other with similar force, regardless of wear or seized pistons. There are two different methods:

![]()

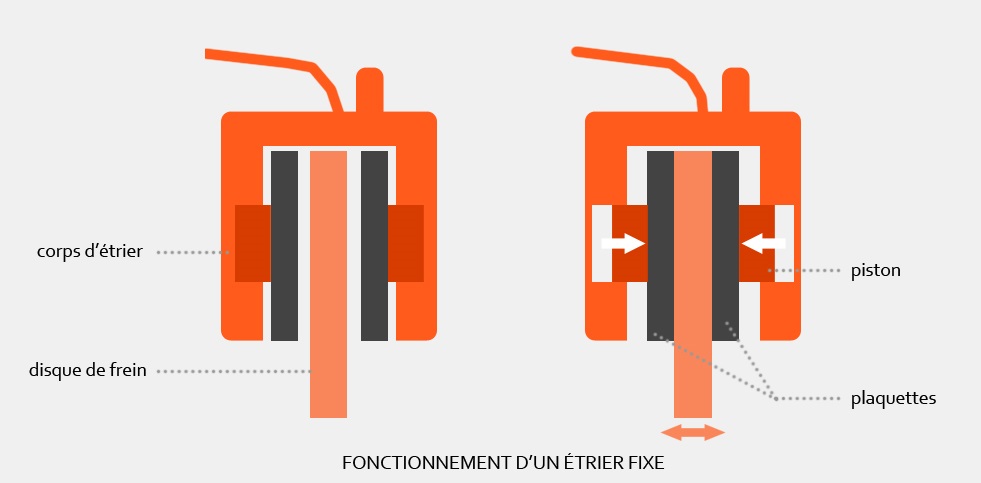

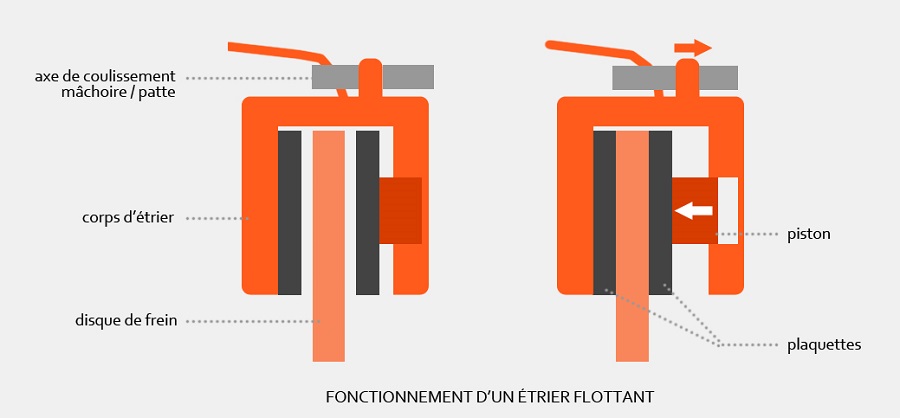

Fixed brake caliper + floating disc

In this case, the pistons work in pairs, facing each other. The mobility required to keep the brake pads correctly centered is provided by the disc itself. It features "floats", also known as drive weights, which allow a few millimeters of lateral play.

![]()

Floating brake caliper + fixed disc

This technology is easily recognized by the fact that the pistons are positioned on the outside only. They do not work face to face. The caliper is made up of two parts: the shoe (the block where the cylinders are located) and the mounting bracket. The latter is screwed to the fork. In this configuration, the jaw slides sideways on the bracket, guaranteeing uniform braking on both pads.

Which technology is more efficient? No Norman answer: the fixed caliper + floating disc combination is the most efficient.

Pistons: size isn't everything

A quick reminder: under the effect of hydraulic pressure, the piston moves and compresses the pads on the disc. So, logically, the more pistons there are, the greater the force exerted, so the harder it brakes? This is partly true. Rear brake calipers, for example, may have only a single piston because they are not used very often. Most front models, on the other hand, have four pistons. Some bikes, like the Suzuki GSX 1400 for example, border on the indecent with no less than six pistons per caliper!

However, the decisive criterion for "powerful" braking is the pressure exerted on the pads. What does this mean? Piston diameter matters. Simply put, the wider they are, the harder they push. So why multiply the pistons? To better distribute the pressure exerted on the pads.

This is also whydifferent diameters can be found on the same caliper, known as asymmetrical pistons. Now, that's a bit of a mouthful. To put it simply, the friction exerted by the linings is greater where the pad "bites" the disc. This is a normal mechanical phenomenon. To counteract this twisting effect, the pressure exerted on the pad is lower in this area, thanks to a slightly narrower cylinder.

Take, for example, the brilliant N640 with its 6 pistons. The one closest to the attack measures 22mm in diameter, the next 25mm, while the furthest one is 30mm. The pressure is uniform, making the most of the entire pad surface. Fantastic!

What's the difference between axial and radial articulation?

So what exactly are we talking about? Simply the way the caliper is attached to the fork.

![]()

Axial articulation between caliper and fork

On an axial model, the body is held in place with bolts perpendicular to the disc, and this presents a problem. During braking, the friction exerted on the brake pads twists the caliper. Intrinsically, it is forced into rotation. Not good.

![]()

Radial joint between caliper and fork

This device takes the torsion worry out of the equation. How is this achieved? By aligning the fixing screws in the same plane as the disc. This has two advantages:

- 1 - this system is much more rigid, as it "works" in the same axis as the wheel rotation. As a result, brake pad alignment is more precise, and there's no tendency for them to twist.

- 2 - it's much more modular. In fact, if you decide to opt for a disproportionately wide disc, such as an oversize 320mm, all you have to do is add spacers to move the caliper away from the wheel axle.

For these two reasons - but above all for rigidity and precision - the radial joint is the only one you'll find in competition.

How to choose new brake calipers

Now that we've listed the characteristics of a caliper, let's move on to the part that interests you most: how to choose them? But before we do, a quick reminder: touching your bike's brakes is a bit like going on a mushroom hunt. You've got to be sure of what you're doing, otherwise you've got a 50/50 chance of going over. And yeah, it's a crucial safety device, so don't mess around with it.

![]()

First of all, check that your bike's current braking system is impeccable.

Why change your calipers? To improve braking efficiency? Well, yes. But before you consider replacing them, you need to make sure that your current system is in perfect condition. This should be the last step after you've: bled your brake fluid, installed new brake pads, rebuilt your calipers, installed new brake hoses, opted for a higher-performance master cylinder.

----> Nissin brake master cylinder radial SPORT Gold 19mm silver lever

![]()

What should I look for when changing brake calipers?

Choose a model of the same type (floating or fixed), with the same articulation (radial or axial), with the same distance between the fixing screws and compatible with the disc dimensions (offset, thickness and diameters). To put it simply, you need to be sure of your bike's compatibility.

What room for manoeuvre is there in this case? First, you can choose a better-quality block from a specialist brand. That's why we only offer Nissin models, the benchmark in our opinion. Secondly, you can opt for a product with more pistons for greater precision. 2nd advantage? Wider pads mean a larger friction surface, and inevitably better braking.

We hope this article has given you more answers than questions. The good news? We're devoting another article to rebuilding your bike's brake calipers. It includes a step-by-step tutorial on how to dismantle, inspect and scrub your calipers, before you consider replacing them.

.

.

.

.

Image credits: header photo and photo with several motorcycles, images from freepik

Our last posts

#interviewmotarde #etonvaoumaintenant #motardevoyageuse #voyagemoto

#hivernale #millevaches #équipementmotard #aventuresmichel

#aventuresmichel #hardefitour #raidenduro #tout-terrain

Aucun produit